The world is undergoing a dramatic shift towards sustainable energy, and at the heart of this transformation lies the revolution in battery production. As we move away from fossil fuels to embrace renewable energy sources like solar and wind, the demand for efficient, high-capacity energy storage has never been greater. Batteries are no longer just components of smartphones and laptops—they are pivotal to the future of electric vehicles (EVs), grid storage, and even portable power solutions in remote areas. The future of battery production is not just about improving energy density and longevity; it’s about reimagining how batteries are designed, manufactured, and integrated into our daily lives to create a cleaner, greener planet.

One of the most significant developments shaping the future of battery coating machine battery production is the advancement of solid-state battery technology. Traditional lithium-ion batteries, while effective, rely on liquid electrolytes, which can pose safety risks due to their flammability and potential for leakage. Solid-state batteries, on the other hand, use solid electrolytes, which are not only safer but also allow for greater energy density. This means that devices and vehicles powered by solid-state batteries can run longer on a single charge and have a longer lifespan overall. Companies like Toyota and QuantumScape are at the forefront of this technology, aiming to commercialize solid-state batteries for electric vehicles within the next few years. The adoption of solid-state technology could drastically reduce charging times, increase driving ranges for EVs, and significantly improve the overall safety of battery systems.

Another critical factor revolutionizing battery production is the focus on sustainability and the circular economy. As the demand for batteries grows, so does the need for raw materials like lithium, cobalt, and nickel. However, the mining and processing of these materials come with environmental and ethical concerns, including habitat destruction, water usage, and poor labor conditions in some regions. To address these issues, battery manufacturers are investing in recycling technologies that can recover valuable materials from used batteries. Companies like Redwood Materials and Li-Cycle are pioneering advanced recycling methods that not only reduce the need for new mining but also lower the environmental footprint of battery production. In the future, we can expect a more circular battery economy, where materials are continually reused, minimizing waste and conserving natural resources.

The evolution of battery production is also being driven by breakthroughs in materials science. Researchers are exploring alternatives to traditional lithium-based chemistries to create batteries that are cheaper, more efficient, and environmentally friendly. For example, lithium-sulfur batteries have the potential to offer much higher energy densities than current lithium-ion batteries, making them ideal for applications where weight is a critical factor, such as in aerospace and drones. Similarly, sodium-ion batteries are emerging as a promising alternative, particularly because sodium is abundant and inexpensive compared to lithium. While these technologies are still in the development phase, they hold the promise of reducing costs, improving performance, and diversifying the supply chain for battery materials, making energy storage more accessible worldwide.

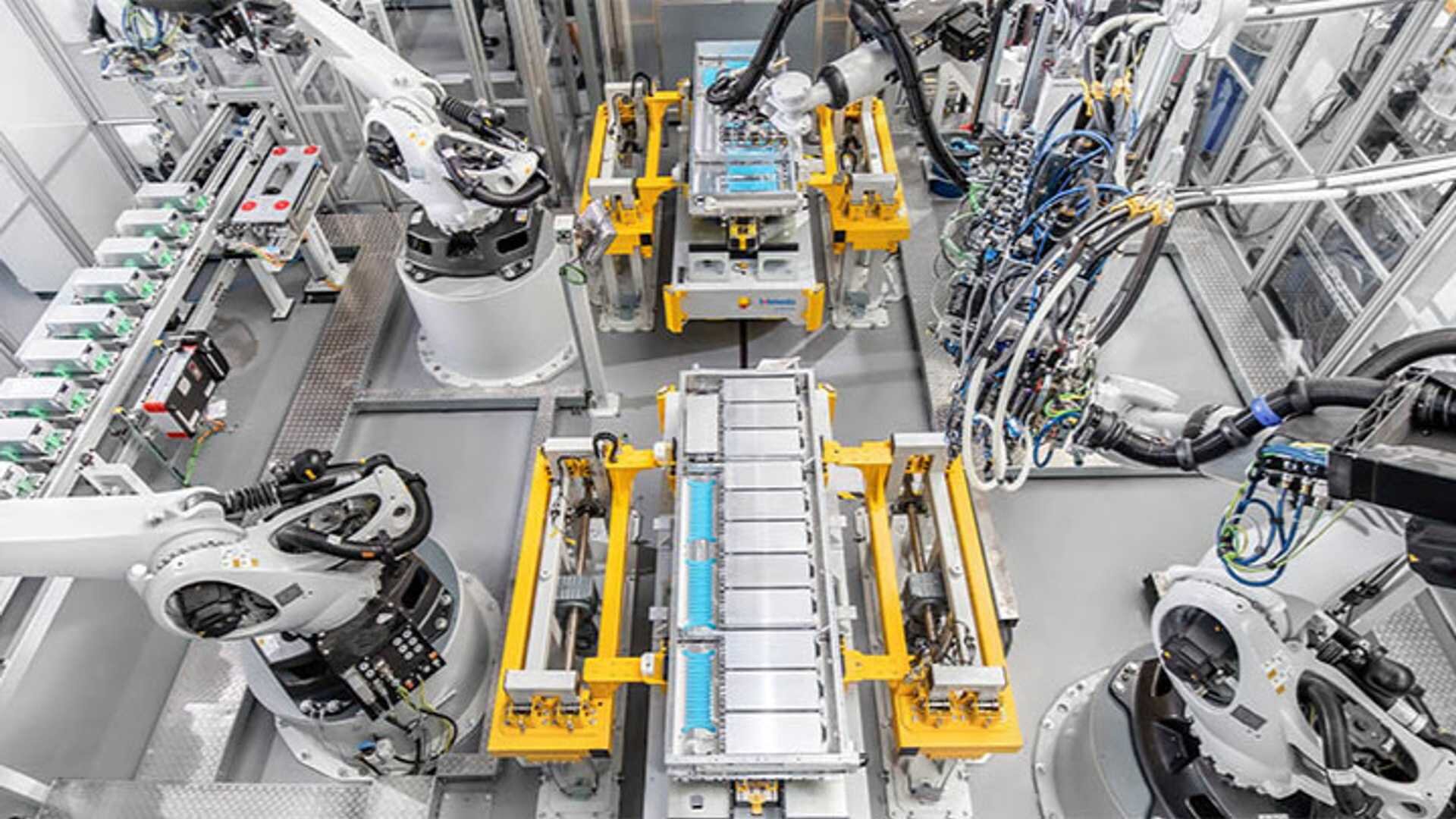

The future of battery production is not solely dependent on technological innovation—it also hinges on scaling up manufacturing capabilities to meet global demand. Gigafactories, large-scale battery production facilities, are being built worldwide to produce batteries at unprecedented rates. Tesla’s Gigafactories, CATL’s massive plants in China, and Europe’s growing network of battery facilities are just a few examples of this trend. These factories are designed not only to increase production capacity but also to improve efficiency through automation and advanced manufacturing techniques. The economies of scale achieved by these facilities help reduce the cost of batteries, making electric vehicles and renewable energy storage solutions more affordable for consumers. Additionally, localizing battery production reduces reliance on long, complex supply chains, enhancing energy security for many nations.

Energy storage for the power grid represents another frontier in the battery revolution. As renewable energy sources like solar and wind become more prevalent, the need for reliable, large-scale energy storage solutions grows. Unlike fossil fuels, which provide consistent energy output, renewable sources are intermittent—solar power depends on sunlight, and wind energy relies on wind conditions. Advanced battery systems can store excess energy generated during peak production times and release it when demand is high or when renewable generation is low. This capability is essential for stabilizing the grid and ensuring a constant, reliable energy supply. Technologies like flow batteries and advanced lithium-ion grid storage systems are being deployed globally to support this transition. As these technologies mature, they will play a critical role in enabling a resilient, renewable-powered energy grid.

Another transformative development in battery production is the integration of artificial intelligence (AI) and machine learning in both the design and manufacturing processes. AI can analyze vast datasets to optimize battery performance, predict failures before they occur, and identify the most efficient production methods. In research and development, machine learning algorithms can accelerate the discovery of new materials by predicting their properties and performance without the need for time-consuming physical experiments. In manufacturing, AI-driven automation ensures precision, reduces waste, and increases production speed. The use of digital twins—virtual replicas of physical battery systems—allows engineers to simulate and test different conditions in real-time, further enhancing battery efficiency and reliability. This fusion of technology and manufacturing is paving the way for smarter, more resilient energy storage solutions.

Global policy and regulatory frameworks are also influencing the future of battery production. Governments around the world are implementing regulations to support the transition to clean energy, including incentives for electric vehicle adoption, subsidies for renewable energy projects, and strict emissions targets. These policies are driving demand for advanced battery technologies and encouraging investment in research, development, and infrastructure. The European Union’s Green Deal, for example, includes ambitious goals for battery production sustainability, aiming to make Europe a leader in the global battery market while reducing environmental impact. In the united states, initiatives like the Inflation Reduction Act are providing substantial funding for clean energy technologies, including domestic battery manufacturing. These policy frameworks are essential for creating an environment where innovation can thrive, and sustainable energy solutions can flourish.

Looking ahead, the future of battery production will likely be characterized by continued diversification and specialization. Rather than relying on a single battery technology, we will see a wide range of solutions tailored to specific applications. High-energy-density batteries will power long-range electric vehicles and aircraft, while durable, long-life batteries will support grid storage and industrial uses. Ultra-fast charging technologies will cater to consumer electronics and public transportation, and flexible, lightweight batteries will enable innovations in wearable technology and medical devices. This diversification ensures that as our energy needs evolve, we have the right tools to meet them efficiently and sustainably.

In conclusion, the future of battery production is a dynamic, rapidly evolving landscape that holds the key to a more sustainable and energy-efficient world. Advances in solid-state technology, sustainable materials, recycling, AI integration, and large-scale manufacturing are revolutionizing how we store and use energy. As these innovations continue to develop, they will not only enhance the performance and affordability of batteries but also play a critical role in addressing the global challenges of climate change and energy security. The battery revolution is more than just a technological shift—it’s the foundation of the clean energy future we are building today.